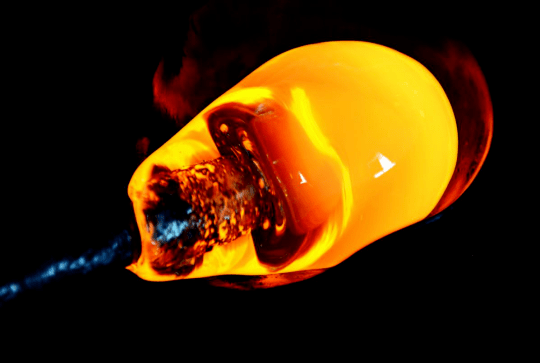

Do you know how the glass lampshade is blown?

Hand blowing mainly uses a hollow iron tube (or stainless steel tube), one end is used to dip the liquid glass, the other end is used for artificial blowing air. The pipe length is about 1.5 ~ 1.7m, the central aperture is 0.5 ~ 1.5cm, and different specifications of the blow pipe can be selected according to the size of the product.

Manual blowing mainly relies on skilled technology and my experience in operation. The operation method seems simple, but it is not easy to skillfully blow products that meet the requirements, especially complex art ornaments.

Most hand-blown glass materials are fused in crucible (there are also in small pool kiln), the change of molding temperature is more complex. At the beginning of the molding temperature is higher, the viscosity of the molten glass is smaller, the operation duration can be slightly longer, the glass in the iron bowl can be a little longer, the bubble can also be slightly cold through, with the crucible in the glass material gradually reduced and the cooling time is prolonged, the operation rhythm of the blowing type must be gradually accelerated. The blowing operation usually requires the cooperation of several people.

Although the blowing technique can embody a strong personality, it is heavily dependent on chance and its limitations are quite obvious. As a result, more artists are turning their attention to combining vertical techniques with other techniques.

Glass production process includes: batching, melting, forming, annealing and other processes. They are introduced as follows:

1: Ingredients

In accordance with the design of the material list, the various raw materials after weighing in a mixer mixed evenly.

2. Melting

The prepared raw materials are heated at high temperature to form a uniform bubble-free glass liquid. This is a very complex physical and chemical process. The melting of glass is carried out in the melting kiln. There are two main types of melting kilns: one is the crucible kiln, the glass material is held in the crucible, the crucible outside the heat. Small crucible kilns only have one crucible, large ones can have as many as 20 crucible. Crucible kiln is gap production, now only optical glass and color glass using crucible kiln production. The other is the pond kiln, the glass material is fused in the kiln, the open fire is heated on the surface of the glass liquid. Most of the glass temperature of the melted in 1300 ~ 1600 ゜ c. Most are heated by flame, but a small number are heated by electric current, which is called electric melting kiln. Now, the pond kiln is continuously produced, the small one can be several meters, the big one can be more than 400 meters.

3: Shape

The molten glass is transformed into a solid product with a fixed shape. Forming must take place within a certain temperature range, a cooling process in which the glass first changes from a viscous liquid to a plastic state and then to a brittle solid state.

Forming methods can be divided into two categories: artificial forming and mechanical forming.

(1) Blowing, with a nichrome alloy blow pipe, pick a ball of glass in the mold while blowing. Mainly used to form glass bubbles, bottles, balls (for glasses).

(2) Drawing, after blowing into a small bubble, another worker with the top plate stick, two people while blowing while pulling mainly used to make glass tube or rod.

(3)Pressing, pick a ball of glass, cut it with scissors, make it fall into the concave die, and then press with a punch. Mainly used to form cups, plates, etc.

(4) Free forming, after picking materials with pliers, scissors, tweezers and other tools directly into crafts.

Step 4 Anneal

Glass undergoes intense temperature and shape changes during forming, which leave thermal stress in the glass. This thermal stress will reduce the strength and thermal stability of glass products. If cooled directly, it is likely to break itself (commonly known as cold explosion of glass) during the cooling process or later during storage, transportation and use. In order to clean up cold explosion, glass products must be annealed after forming. Annealing is to hold or slowly cool over a certain temperature range for a period of time in order to clean or reduce the thermal stress in the glass to an allowable value.

Because manual blowing does not accept machine and mold restrictions, form and color freedom is very high, so the finished product often has high technical appreciation value. At the same time, artificial glass blowing requires more than one person to complete, so the labor cost is high.

We’ve also made a video about hand-blown glass, and if you’re interested, you can check out the facebook link below.

https://fb.watch/iRrxE0ajsP/